A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_URI::$config is deprecated

Filename: core/URI.php

Line Number: 101

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_Router::$uri is deprecated

Filename: core/Router.php

Line Number: 127

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Pagecontent_controller::$benchmark is deprecated

Filename: core/Controller.php

Line Number: 75

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Pagecontent_controller::$hooks is deprecated

Filename: core/Controller.php

Line Number: 75

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Pagecontent_controller::$config is deprecated

Filename: core/Controller.php

Line Number: 75

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Pagecontent_controller::$log is deprecated

Filename: core/Controller.php

Line Number: 75

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Pagecontent_controller::$utf8 is deprecated

Filename: core/Controller.php

Line Number: 75

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Pagecontent_controller::$uri is deprecated

Filename: core/Controller.php

Line Number: 75

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Pagecontent_controller::$exceptions is deprecated

Filename: core/Controller.php

Line Number: 75

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Pagecontent_controller::$router is deprecated

Filename: core/Controller.php

Line Number: 75

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Pagecontent_controller::$output is deprecated

Filename: core/Controller.php

Line Number: 75

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Pagecontent_controller::$security is deprecated

Filename: core/Controller.php

Line Number: 75

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Pagecontent_controller::$input is deprecated

Filename: core/Controller.php

Line Number: 75

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Pagecontent_controller::$lang is deprecated

Filename: core/Controller.php

Line Number: 75

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Pagecontent_controller::$load is deprecated

Filename: core/Controller.php

Line Number: 78

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Pagecontent_controller::$db is deprecated

Filename: core/Loader.php

Line Number: 396

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/helpers/my_helper.php

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_DB_mysqli_driver::$failover is deprecated

Filename: database/DB_driver.php

Line Number: 371

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/helpers/my_helper.php

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: 8192

Message: Return type of CI_Session_files_driver::open($save_path, $name) should either be compatible with SessionHandlerInterface::open(string $path, string $name): bool, or the #[\ReturnTypeWillChange] attribute should be used to temporarily suppress the notice

Filename: drivers/Session_files_driver.php

Line Number: 132

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/helpers/my_helper.php

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: 8192

Message: Return type of CI_Session_files_driver::close() should either be compatible with SessionHandlerInterface::close(): bool, or the #[\ReturnTypeWillChange] attribute should be used to temporarily suppress the notice

Filename: drivers/Session_files_driver.php

Line Number: 294

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/helpers/my_helper.php

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: 8192

Message: Return type of CI_Session_files_driver::read($session_id) should either be compatible with SessionHandlerInterface::read(string $id): string|false, or the #[\ReturnTypeWillChange] attribute should be used to temporarily suppress the notice

Filename: drivers/Session_files_driver.php

Line Number: 168

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/helpers/my_helper.php

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: 8192

Message: Return type of CI_Session_files_driver::write($session_id, $session_data) should either be compatible with SessionHandlerInterface::write(string $id, string $data): bool, or the #[\ReturnTypeWillChange] attribute should be used to temporarily suppress the notice

Filename: drivers/Session_files_driver.php

Line Number: 237

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/helpers/my_helper.php

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: 8192

Message: Return type of CI_Session_files_driver::destroy($session_id) should either be compatible with SessionHandlerInterface::destroy(string $id): bool, or the #[\ReturnTypeWillChange] attribute should be used to temporarily suppress the notice

Filename: drivers/Session_files_driver.php

Line Number: 317

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/helpers/my_helper.php

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: 8192

Message: Return type of CI_Session_files_driver::gc($maxlifetime) should either be compatible with SessionHandlerInterface::gc(int $max_lifetime): int|false, or the #[\ReturnTypeWillChange] attribute should be used to temporarily suppress the notice

Filename: drivers/Session_files_driver.php

Line Number: 358

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/helpers/my_helper.php

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: Warning

Message: ini_set(): Session ini settings cannot be changed after headers have already been sent

Filename: Session/Session.php

Line Number: 282

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/helpers/my_helper.php

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: Warning

Message: session_set_cookie_params(): Session cookie parameters cannot be changed after headers have already been sent

Filename: Session/Session.php

Line Number: 289

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/helpers/my_helper.php

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: Warning

Message: ini_set(): Session ini settings cannot be changed after headers have already been sent

Filename: Session/Session.php

Line Number: 304

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/helpers/my_helper.php

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: Warning

Message: ini_set(): Session ini settings cannot be changed after headers have already been sent

Filename: Session/Session.php

Line Number: 314

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/helpers/my_helper.php

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: Warning

Message: ini_set(): Session ini settings cannot be changed after headers have already been sent

Filename: Session/Session.php

Line Number: 315

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/helpers/my_helper.php

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: Warning

Message: ini_set(): Session ini settings cannot be changed after headers have already been sent

Filename: Session/Session.php

Line Number: 316

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/helpers/my_helper.php

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: Warning

Message: ini_set(): Session ini settings cannot be changed after headers have already been sent

Filename: Session/Session.php

Line Number: 317

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/helpers/my_helper.php

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: Warning

Message: ini_set(): Session ini settings cannot be changed after headers have already been sent

Filename: Session/Session.php

Line Number: 375

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/helpers/my_helper.php

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: Warning

Message: session_set_save_handler(): Session save handler cannot be changed after headers have already been sent

Filename: Session/Session.php

Line Number: 110

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/helpers/my_helper.php

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: Warning

Message: session_start(): Session cannot be started after headers have already been sent

Filename: Session/Session.php

Line Number: 143

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/helpers/my_helper.php

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Pagecontent_controller::$session is deprecated

Filename: core/Loader.php

Line Number: 1283

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/helpers/my_helper.php

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Pagecontent_controller::$form_validation is deprecated

Filename: core/Loader.php

Line Number: 1283

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Pagecontent_controller::$email is deprecated

Filename: core/Loader.php

Line Number: 1283

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Pagecontent_controller::$cart is deprecated

Filename: core/Loader.php

Line Number: 1283

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property Pagecontent_controller::$Pagecontent_model is deprecated

Filename: core/Loader.php

Line Number: 358

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_Loader::$benchmark is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_Loader::$hooks is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_Loader::$config is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_Loader::$log is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_Loader::$utf8 is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_Loader::$uri is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_Loader::$exceptions is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_Loader::$router is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_Loader::$output is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_Loader::$security is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_Loader::$input is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_Loader::$lang is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_Loader::$load is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_Loader::$db is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_Loader::$session is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_Loader::$form_validation is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_Loader::$email is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_Loader::$cart is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

A PHP Error was encountered

Severity: 8192

Message: Creation of dynamic property CI_Loader::$Pagecontent_model is deprecated

Filename: core/Loader.php

Line Number: 931

Backtrace:

File: /home4/techwelfare/public_html/carlacorp/application/frontend/controllers/Pagecontent_controller.php

File: /home4/techwelfare/public_html/carlacorp/index.php

Our Process

At Carla, we live by four standard principles: Quality, Service, Trust, and Dependability. All of our manufacturing is done in our main factory located in East Providence, RI or our Los Angeles, CA Design Studio. Some of our processes are unique to Carla which makes our jewelry so distinct.

WAX

Using a rubber mold and heated wax, we inject the wax into the mold to create a pattern for our other processes. Each piece is then cleaned by hand to create a high-quality model.

LOST WAX CASTING

After building a 'tree'' of plastic patterns, we insert the tree into a canister, which is then filled with a plaster-like substance. During the heating process, the patterns melt and evaporate leaving negative images within the plaster. We then melt gold or silver and using a casting machine, inject it into the canister to fill in the negative images.

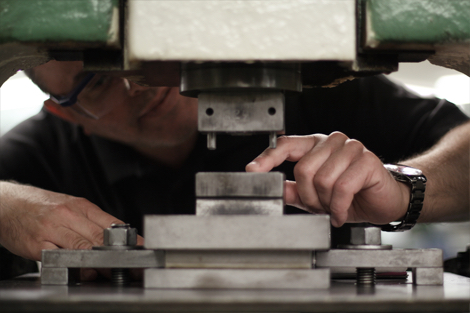

PRESS

Our different styles and shapes are created using custom dies and tools, which are made using 40-ton power presses. The presses imprint a shape into a gold or silver sheet, which is then sent to solder to be fused together.

ELECTROFORM

Using our wax patterns, precious metal is deposited over the wax patterns. It is a proprietary process similar to plating. Electroform gives us the ability to produce large styles that are hollow, lightweight and durable. We are the only manufacturer in the US to use this process.

SOLDER

Our other components are soldered together by hand using high-intensity torches. Some are then put through a high intensity oven to seal the tacked pieces together.

HALLMARK

Every piece of our jewelry is hallmarked with our signature ''quality stamp.'' Ensuring our customers that they are receiving Carla or Nancy B 14KT or Silver. It's our promise to you that it is of the quality you deserve.

STONESETTING

Our master craftsmen meticulously form metal prongs and bezels around precious and Semi-precious stones. Each style is individually hand made and set by our experienced stone setters both here in RI and in CA.

TUBBING

To show our true shine, all of our products go through a tubbing process that is unique to the materials in the product. The tubs contain various abrasives to go from a raw state to a smooth finish, so they are ready to go to polish.

POLISH

Using a variety of buffs and compounds, our trained craftsmen polish every piece by hand to create a high-quality finish on all of our jewelry. ??

PLATE

All of our jewelry is finished off with a Rhodium or Hamilton finish to give our consistent Carla / Nancy B Color. The plating process can be done at different stages depending on the stone within the style.

GLUING

We also glue pearls and various stones using a two-part epoxy. We choose to use epoxy because of its strength to guarantee your jewelry to last a lifetime

INSPECT

After the manufacturing process, our jewelry has one more phase to go through before being shipped. Inspection is a very important process as each piece we make is thoroughly inspected by hand and signed off by one of our inspectors.

Carlacorp